The 30 30 brake chamber is a critical part of heavy-duty vehicle braking systems. It converts air pressure into mechanical force, helping you stop large vehicles safely. This component ensures reliable braking, even under tough conditions. Without it, controlling heavy loads becomes risky. Its design prioritizes safety, making it essential for smooth and secure operations.

Key Takeaways

- The 30 30 brake chamber is important for big vehicles. It changes air pressure into force to help them stop safely.

- Checking and cleaning the brake chamber often can stop expensive fixes. It also keeps the brakes working well.

- Knowing parts like diaphragms and push rods helps find problems. This helps you take care of your brakes better.

Understanding the 30 30 Brake Chamber

What is a 30 30 brake chamber?

You’ve probably heard the term “30 30 brake chamber” if you’re familiar with heavy-duty vehicles. But what exactly is it? A 30 30 brake chamber is a specialized component in air brake systems. It’s designed to convert compressed air into mechanical force, which helps stop large vehicles like trucks and buses. The name “30 30″ refers to the size of the chamber’s two diaphragms, each measuring 30 square inches. This dual-diaphragm setup gives it the power to handle the intense braking demands of heavy loads. Without this part, air brakes wouldn’t function effectively.

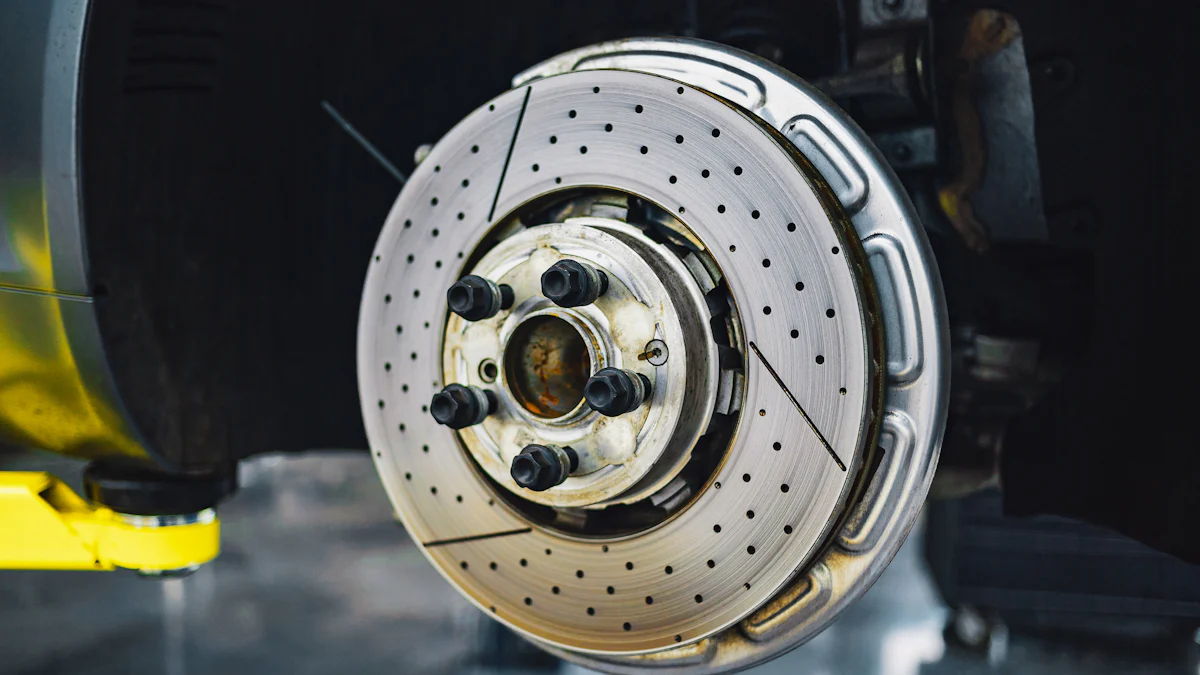

Key features and design

The 30 30 brake chamber stands out because of its robust design. It has two main sections: the service chamber and the spring brake chamber. The service chamber handles regular braking, while the spring brake chamber acts as a fail-safe in emergencies. Inside, you’ll find durable diaphragms, a push rod, and a powerful spring. The external casing is built to withstand harsh conditions, ensuring long-term reliability. Its ports allow compressed air to flow in and out, making the braking process smooth and efficient.

Applications in heavy-duty vehicles

You’ll find 30 30 brake chambers in a variety of heavy-duty vehicles. They’re commonly used in semi-trucks, trailers, and buses. These vehicles rely on air brake systems to manage their massive weight. The 30 30 brake chamber ensures they can stop safely, even when carrying heavy cargo. It’s a vital component for maintaining control on steep hills or during sudden stops.

Components of a Brake Chamber

Diaphragms and their function

The diaphragms inside a brake chamber are the heart of its operation. These flexible rubber components separate the air pressure from the mechanical parts. When compressed air enters the chamber, it pushes against the diaphragm. This movement creates the force needed to activate the push rod and apply the brakes. Without the diaphragm, the air pressure wouldn’t translate into mechanical action. You’ll find that these diaphragms are built to handle high pressure and resist wear, ensuring they last through tough conditions.

Push rods, springs, and external casing

The push rod, springs, and external casing work together to make the brake chamber durable and effective. The push rod connects the diaphragm to the braking mechanism. When the diaphragm moves, the push rod transfers that motion to engage the brakes. The springs inside the chamber play a dual role. They help release the brakes when you’re not applying pressure and act as a fail-safe during emergencies. The external casing protects all these components from dirt, moisture, and damage. It’s designed to withstand harsh environments, keeping the internal parts safe and functional.

Ports and their role in air brake systems

The ports on a brake chamber are small but essential. They allow compressed air to flow in and out of the chamber. Each port has a specific role. One port directs air into the service chamber for regular braking. Another port manages air for the spring brake chamber, which activates during parking or emergencies. These ports ensure the air brake system operates smoothly and efficiently. If a port gets clogged or damaged, it can disrupt the entire braking process. Regular checks can help you avoid such issues.

How a Brake Chamber Works

The dual-diaphragm mechanism

The dual-diaphragm mechanism is what makes the 30 30 brake chamber so effective. It uses two diaphragms, each with a specific role. The first diaphragm operates the service brake, which handles everyday braking. The second diaphragm controls the spring brake, which kicks in during emergencies or when the vehicle is parked. These diaphragms work independently but in harmony. This setup ensures your vehicle has reliable braking power in all situations. You can think of it as having a backup system built right in.

Tip: Regularly inspect the diaphragms for wear and tear. A small crack can lead to big problems down the road.

Interaction with compressed air

Compressed air is the lifeblood of the brake chamber. When you press the brake pedal, air flows into the chamber through its ports. This air pressure pushes against the diaphragm, creating the force needed to activate the brakes. The amount of air pressure determines how much braking force is applied. If the air supply is interrupted or leaks occur, the braking system won’t work as it should. That’s why keeping the air system in good shape is so important.

The braking process explained

Here’s how the braking process works step by step:

- You press the brake pedal.

- Compressed air enters the service chamber.

- The air pushes the diaphragm, moving the push rod.

- The push rod engages the brake mechanism, slowing the vehicle.

In emergency situations, the spring brake takes over. It uses a powerful spring to apply the brakes automatically, even if the air system fails. This dual-action process ensures your vehicle stops safely every time.

Note: Always test your brakes before hitting the road. It’s a quick way to catch potential issues early.

Maintenance and Troubleshooting

Tips for regular inspection and cleaning

Keeping your brake chamber in top shape starts with regular inspections. Check for visible damage like cracks or rust on the external casing. Look at the ports to ensure they’re free of dirt or debris. A clogged port can mess with the airflow and reduce braking efficiency. Cleaning the chamber is simple. Use a soft brush or cloth to wipe away grime. Avoid using harsh chemicals that might damage the rubber diaphragms. Make it a habit to inspect the chamber every few weeks, especially if you drive in harsh conditions.

Tip: Don’t forget to check the air hoses connected to the chamber. A loose or damaged hose can cause air leaks.

Identifying and addressing common issues

Sometimes, problems pop up even with regular maintenance. One common issue is air leaks. You might hear a hissing sound or notice reduced braking power. Another problem could be a stuck push rod, which can lead to uneven braking. If the spring brake doesn’t release, it might be due to a broken spring or diaphragm. When you spot these issues, act fast. Ignoring them can lead to bigger, costlier repairs.

Alert: If you’re unsure about a problem, consult a professional. Guesswork can make things worse.

Guidelines for replacement and repairs

Replacing a brake chamber isn’t something you’ll do often, but it’s necessary when wear and tear take their toll. Always use a chamber that matches your vehicle’s specifications. Before starting, release all air pressure from the system to avoid accidents. Follow the manufacturer’s instructions for installation. If you’re not confident, leave it to a mechanic. Proper installation ensures your brakes work as they should.

Note: After replacing the chamber, test the brakes to confirm everything’s working perfectly.

The 30 30 brake chamber plays a huge role in keeping your vehicle safe. Regular maintenance and quick troubleshooting can save you from costly repairs and dangerous situations. Always inspect it for wear, clean it often, and replace it when needed. These simple steps will keep your brakes reliable and your journeys stress-free.

FAQ

What does “30 30″ mean in a brake chamber?

The “30 30″ refers to the size of the two diaphragms, each measuring 30 square inches. This design provides the power needed for heavy-duty braking.

How often should you inspect a 30 30 brake chamber?

Inspect it every few weeks, especially if you drive in harsh conditions. Regular checks help catch issues like air leaks or worn diaphragms early.

Can you replace a brake chamber yourself?

Yes, but only if you’re confident in your skills. Always release air pressure first. If unsure, it’s safer to consult a professional mechanic.

Tip: Always test your brakes after replacing or repairing the chamber to ensure everything works perfectly.

Post time: Jan-17-2025