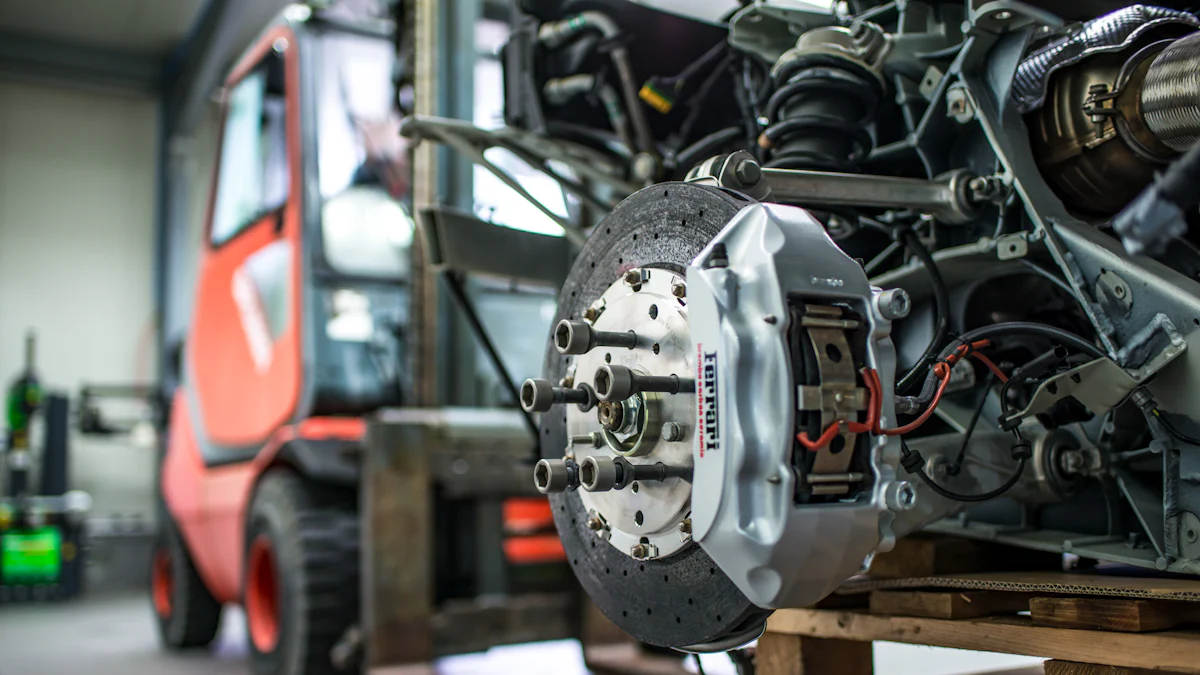

The brake caliper plays a vital role in your truck’s braking system. It applies pressure to the brake pads, which then grip the rotor to slow or stop the vehicle. This process ensures reliable braking performance. By maintaining the brake caliper, you enhance your truck’s safety and reduce the risk of accidents.

How a Truck Brake Caliper Works

The role of hydraulic pressure in brake caliper operation

Hydraulic pressure powers the brake caliper in your truck. When you press the brake pedal, the master cylinder generates hydraulic pressure by pushing brake fluid through the brake lines. This pressure travels to the brake caliper, forcing its pistons to move. The pistons then press the brake pads against the rotor. This contact creates the friction needed to slow or stop your truck.

Hydraulic systems are efficient because they evenly distribute pressure. This ensures that all wheels receive the same braking force. Without hydraulic pressure, the brake caliper would not function effectively, leading to poor braking performance.

Step-by-step process of how brake calipers engage and release the brake pads

- Brake pedal pressed: When you step on the brake pedal, the master cylinder activates and sends hydraulic pressure to the brake caliper.

- Pistons engage: The hydraulic pressure pushes the pistons inside the brake caliper.

- Brake pads contact the rotor: The pistons press the brake pads against the spinning rotor. This creates friction, which slows the truck.

- Vehicle slows or stops: The friction between the brake pads and rotor reduces the wheel’s rotation, bringing the truck to a halt.

- Brake pedal released: When you release the brake pedal, the hydraulic pressure decreases. The pistons retract, pulling the brake pads away from the rotor.

This process repeats every time you use the brakes, ensuring your truck stops safely and efficiently.

Components of a Truck Brake Caliper

Pistons and their function in applying pressure

The pistons inside the brake caliper are essential for creating the force needed to stop your truck. These cylindrical components sit within the caliper housing and move when hydraulic pressure is applied. When you press the brake pedal, the hydraulic fluid pushes the pistons outward. This movement forces the brake pads against the rotor, generating the friction required to slow the wheels.

Pistons are typically made from durable materials like steel or aluminum to withstand high pressure and heat. Some brake calipers have multiple pistons to distribute pressure evenly across the brake pads. This ensures consistent braking performance and reduces wear on the pads.

Brake pads and their interaction with the rotor

Brake pads are the parts that directly contact the rotor to create friction. They are mounted inside the brake caliper and are pressed against the rotor by the pistons. When the pads grip the rotor, the truck slows down or stops.

Brake pads are made from materials like ceramic, metallic, or organic compounds. These materials are designed to handle extreme heat and pressure without breaking down. Over time, the pads wear out and need replacement. Regular inspections help you avoid reduced braking efficiency caused by worn-out pads.

The caliper housing and its role in the braking system

The caliper housing holds all the components of the brake caliper together. It provides a sturdy structure for the pistons, brake pads, and other parts to function properly. The housing is usually made from cast iron or aluminum to ensure strength and durability.

The housing also protects the internal components from dirt, debris, and moisture. A well-maintained caliper housing ensures the entire braking system operates smoothly. If the housing becomes damaged or corroded, it can affect the performance of the brake caliper and compromise your truck’s safety.

Types of Brake Calipers

Floating calipers: Features and benefits

Floating calipers, also called sliding calipers, move laterally on guide pins. These calipers have a single piston on one side of the rotor. When you press the brake pedal, the piston pushes the brake pad against the rotor. At the same time, the caliper slides to pull the opposite pad into contact with the rotor. This design ensures even pressure on both sides of the rotor.

Floating calipers are lightweight and cost-effective. They are common in trucks because they are easier to maintain and replace. However, they may not provide as much braking force as other types, making them better suited for lighter loads or everyday driving.

Fixed calipers: Features and benefits

Fixed calipers remain stationary and do not slide. They have pistons on both sides of the rotor. When you apply the brakes, these pistons press the brake pads against the rotor from both sides simultaneously. This design delivers stronger and more consistent braking performance.

Fixed calipers are ideal for heavy-duty trucks or vehicles that carry large loads. They offer better heat dissipation, reducing the risk of brake fade during extended use. However, they are more expensive and require more effort to maintain compared to floating calipers.

Sliding calipers: Features and benefits

Sliding calipers function similarly to floating calipers. They also move laterally to apply pressure to the brake pads. The main difference lies in their mounting system. Sliding calipers use a bracket to hold the caliper in place, allowing it to slide back and forth.

These calipers are simple in design and affordable. They are commonly used in trucks because they are reliable and easy to service. However, like floating calipers, they may not provide the same level of braking power as fixed calipers.

Tip: Regularly inspect sliding calipers for wear or sticking to ensure smooth operation.

Common Issues and Maintenance Tips

Signs of malfunction (e.g., noise, uneven braking, leaks)

You can identify a malfunctioning brake caliper by paying attention to specific warning signs. Unusual noises, like squealing or grinding, often indicate worn-out brake pads or misaligned components. Uneven braking, where the truck pulls to one side, suggests that one caliper may not be functioning properly. Leaking brake fluid around the caliper is another red flag. This leak reduces hydraulic pressure, which compromises braking performance. Always address these issues promptly to avoid further damage.

Common problems (e.g., sticking calipers, corrosion)

Sticking calipers are a frequent issue. When a caliper sticks, it fails to release the brake pads fully, causing excessive wear and overheating. Corrosion is another common problem, especially in areas with harsh weather or road salt. Rust can damage the caliper housing and pistons, leading to reduced efficiency. Over time, these problems can escalate, affecting the entire braking system.

Maintenance tips to ensure longevity and performance

Regular maintenance keeps your brake caliper in top condition. Inspect the calipers during routine brake checks. Clean them to remove dirt and debris that can cause sticking. Lubricate the guide pins and moving parts to ensure smooth operation. Replace worn-out brake pads promptly to prevent damage to the rotor and caliper. If you notice any signs of corrosion, address them immediately to avoid further deterioration. These simple steps help extend the life of your calipers and ensure safe braking.

Brake calipers are essential for your truck’s safety and braking performance. They ensure reliable stopping power during every drive. Regular inspections help you catch issues early, while proper maintenance extends their lifespan. By prioritizing these steps, you reduce the risk of failures and keep your truck operating safely and efficiently.

Post time: Jan-14-2025