Trucks rely on specialized brake systems to handle heavy loads and long distances. These systems, such as air brakes and hydraulic brakes, ensure safe and efficient operation. Each truck brake system is designed to meet specific demands, making it essential for you to understand how they work to maintain safety and performance.

Key Takeaways

- Air brakes work well for big trucks. They use compressed air to stop and have safety features that activate if air pressure gets too low.

- Hydraulic brakes give smooth and quick stopping for smaller trucks. It’s important to check them often to avoid leaks and stay safe.

- Picking the right brakes depends on your truck’s size and use. Checking and fixing brakes often helps them last longer.

Air Brakes in Truck Brake Systems

How Air Brakes Work

Air brakes are a common feature in heavy-duty vehicles like trucks. This system uses compressed air to activate the brakes. When you press the brake pedal, air flows through the system, pushing a piston that applies pressure to the brake pads or shoes. This pressure slows down or stops the truck. Unlike hydraulic brakes, air brakes rely on air pressure instead of fluid, making them more reliable for large vehicles.

Air brakes also include a safety feature. If the system loses air pressure, the brakes automatically engage. This prevents accidents caused by brake failure. You can find air brakes in many trucks because they handle heavy loads effectively and provide consistent performance over long distances.

Pros and Cons of Air Brakes

Air brakes offer several advantages. They are durable and can handle the demands of a heavy truck brake system. Their design ensures safety, even in cases of air pressure loss. Additionally, air brakes are easier to maintain compared to hydraulic systems.

However, air brakes have some drawbacks. They require regular inspections to ensure proper air pressure levels. The system can also be noisy, which might be distracting. Furthermore, air brakes may take longer to respond compared to other systems, especially if not maintained properly.

Understanding these pros and cons helps you decide if air brakes suit your truck brake system needs.

Hydraulic Brakes in Truck Brake Systems

How Hydraulic Brakes Work

Hydraulic brakes use fluid to transfer force from the brake pedal to the wheels. When you press the brake pedal, it pushes a piston inside the master cylinder. This action forces brake fluid through the brake lines to the wheel cylinders or calipers. The fluid pressure activates pistons at the wheels, which press the brake pads or shoes against the rotors or drums. This friction slows down or stops the truck.

Hydraulic brakes rely on the incompressibility of fluid to deliver consistent braking power. They are commonly found in lighter trucks and vehicles that do not require the heavy-duty capabilities of air brakes.

Tip: Always check the brake fluid level in your truck. Low fluid can reduce braking efficiency and compromise safety.

Pros and Cons of Hydraulic Brakes

Hydraulic brakes offer several benefits. They provide smooth and responsive braking, which makes them ideal for lighter trucks. The system is quieter compared to air brakes, and it requires less maintenance in terms of air pressure checks.

However, hydraulic brakes have limitations. They are less effective for heavy loads, as the system can overheat under extreme pressure. Leaks in the brake lines can also lead to brake failure. Regular inspections and maintenance are essential to keep the system functioning properly.

Understanding the strengths and weaknesses of hydraulic brakes helps you decide if they are suitable for your truck brake system.

Disc Brakes vs. Drum Brakes in Truck Brake Systems

How Disc Brakes Work

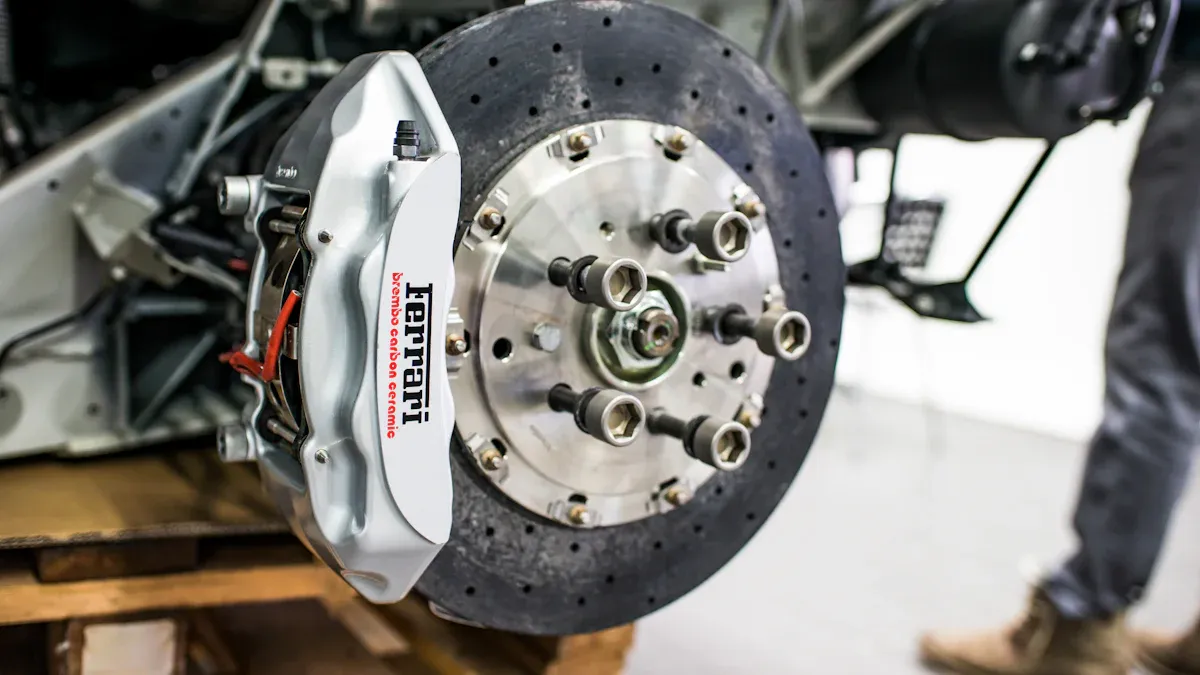

Disc brakes use a rotor, caliper, and brake pads to stop your truck. When you press the brake pedal, hydraulic pressure forces the caliper to squeeze the brake pads against the spinning rotor. This action creates friction, which slows the wheel. Disc brakes are exposed to air, which helps them cool down quickly. This design makes them effective for high-performance braking, especially during repeated use.

Note: Disc brakes are often found in modern trucks due to their superior stopping power and heat resistance.

How Drum Brakes Work

Drum brakes use a drum and brake shoes to create friction. When you press the brake pedal, hydraulic pressure pushes the brake shoes outward against the inside of the drum. This friction slows the wheel. Drum brakes are enclosed, which protects them from dirt and debris. However, they can overheat more easily because the enclosed design traps heat.

Comparing Disc and Drum Brakes

Disc brakes offer better performance in terms of stopping power and heat dissipation. They are ideal for trucks that operate in demanding conditions. Drum brakes, on the other hand, are simpler and more cost-effective. They are often used in the rear wheels of trucks to complement disc brakes in the front.

| Feature | Disc Brakes | Drum Brakes |

|---|---|---|

| Heat Dissipation | Excellent | Limited |

| Maintenance | Easier | More frequent |

| Cost | Higher | Lower |

Choosing between these systems depends on your truck brake system’s specific needs and operating conditions.

Transmission Brakes in Truck Brake Systems

How Transmission Brakes Work

Transmission brakes operate differently from other braking systems. Instead of acting directly on the wheels, they work on the drivetrain. When you engage the transmission brake, it applies friction to a drum or disc connected to the transmission. This action slows down or stops the rotation of the drivetrain, which in turn halts the truck.

These brakes are typically activated through a mechanical or hydraulic system. They are often used as parking brakes or emergency brakes because they can hold the vehicle stationary even on steep inclines. Transmission brakes are especially useful in situations where wheel brakes might not provide enough holding power.

Tip: Regularly inspect your transmission brake to ensure it functions properly, especially if you frequently park on slopes.

Applications of Transmission Brakes

You will find transmission brakes in specific types of trucks and heavy-duty vehicles. They are commonly used in off-road trucks, construction equipment, and vehicles that operate in rugged environments. These brakes provide additional safety by preventing the truck from rolling when parked or during emergency stops.

Transmission brakes also play a role in reducing wear on the primary truck brake system. By handling some of the braking tasks, they extend the lifespan of wheel brakes. This makes them a valuable addition to vehicles that face demanding conditions.

Understanding how and where to use transmission brakes can help you maximize safety and efficiency in your truck’s operation.

Choosing the Right Truck Brake System

Factors to Consider

When selecting a truck brake system, you need to evaluate several factors. Start by considering the weight of your truck and the loads it carries. Heavier trucks require more robust braking systems, such as air brakes, to handle the stress. Next, think about the operating environment. Trucks that frequently travel on steep slopes or in extreme weather conditions may benefit from disc brakes due to their superior heat dissipation.

You should also assess the cost and availability of replacement parts. Some systems, like drum brakes, are more affordable to maintain. However, they may not perform as well under heavy use. Finally, consider the ease of maintenance. A system that requires less frequent servicing can save you time and money in the long run.

Tip: Always match the brake system to your truck’s specific needs to ensure safety and efficiency.

Maintenance and Longevity

Proper maintenance extends the lifespan of your truck brake system. Regularly inspect components like brake pads, rotors, and fluid levels. Replace worn-out parts promptly to avoid further damage. Cleaning the system helps prevent dirt and debris from affecting performance.

You should also follow the manufacturer’s guidelines for servicing. For example, air brakes require frequent checks for air pressure and leaks. Hydraulic brakes need regular fluid changes to maintain efficiency. Consistent care ensures your brakes perform reliably and last longer.

Regulatory Compliance

Brake systems in trucks must meet safety regulations. These rules vary by region but often include standards for braking performance, maintenance, and inspections. For example, the Federal Motor Carrier Safety Administration (FMCSA) in the United States sets specific requirements for commercial vehicles.

You must ensure your truck brake system complies with these regulations. Non-compliance can result in fines or accidents. Staying informed about the latest rules helps you avoid legal issues and keeps your truck safe on the road.

Trucks use different brake systems to meet specific needs. Choosing the right system ensures safety and performance. Regular maintenance keeps brakes reliable and extends their lifespan.

Reminder: Learn how your truck’s brake system works. This knowledge helps you stay compliant with regulations and avoid costly repairs.

FAQ

What is the most common brake system used in trucks?

Air brakes are the most common system. They handle heavy loads effectively and include safety features like automatic engagement during air pressure loss.

How often should you inspect truck brakes?

Inspect truck brakes every 3,000 to 5,000 miles. Regular checks ensure safety and prevent costly repairs caused by worn-out components or system failures.

Can you mix disc and drum brakes on a truck?

Yes, many trucks use disc brakes in the front and drum brakes in the rear. This combination balances performance, cost, and durability.

Tip: Always consult your truck’s manual for specific brake system recommendations and maintenance schedules.

Post time: Mar-17-2025